This series mainly focus on the important, mostly used standards (GB/T, ISO, SAE, etc..) for battery testings.

GB/T 38031-2020

1 | Replacing GB/T 31485-2015 and GB/T 31467.3-2015 |

GB/T 38031-2020: All technical contents of this standard are mandatory.

1 | {Pre Conditioning} |

Secondary Cell Safety

Overdischarge Test

a) Charge to Umax according to Pre Conditioning

b) 1C discharge for 90mins

c) Observe for 1h at the test environment temperature

Overcharge Test

a) Charge to Umax according to Pre Conditioning

b) 1/3C charge until reach 1.1 times of Umax or 115% SOC

c) Observe for 1h at the test environment temperature

External Short Circuit Test

a) Charge to Umax according to Pre Conditioning

b) HV+ and HV- shall be subjected to external short circuit for 10mins, and the resistance of external circuit shall be <= 5mΩ

c) Observe for 1h at the test environment temperature

Heating Test

a) Charge to Umax according to Pre Conditioning

b) Heat with the following conditions:

c.1) Lithium-ion: 130±2℃ from the test environment at 5℃/min, keep it for 30mins, then stop heating;

c.2) Ni-MH: 85±2℃ from the test environment at 5℃/min, keep it for 2h, then stop heating;

d) Observe for 1h at the test environment temperature

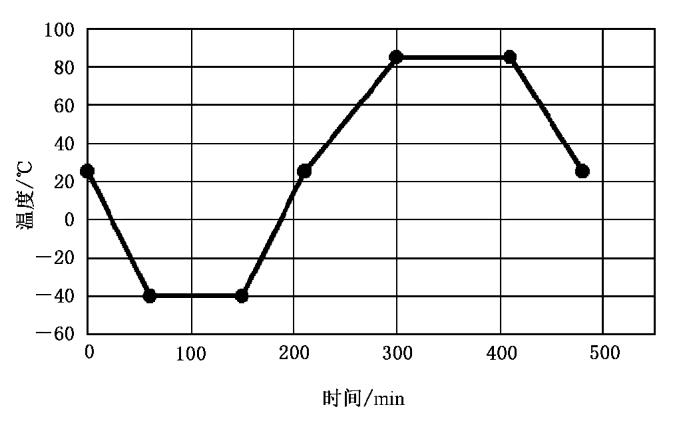

Temperature Cycle Test

a) Charge to Umax according to Pre Conditioning

b) Put the cell into chamber, adjust the temperature of chamber according to Table 1 and Figure 1, and cycle for 5times

c) Observe for 1h at the test environment temperature

Table 1 Temperature and Time for One Cycle of Temperature Cycle Test

| Temperature (℃) | Time Increment (min) | Cumulative Time (min) | Temperature Change Rate (℃/min) |

|---|---|---|---|

| 25 | 0 | 0 | 0 |

| -40 | 60 | 60 | 13/12 |

| -40 | 90 | 150 | 0 |

| 25 | 60 | 210 | 13/12 |

| 85 | 90 | 300 | 2/3 |

| 85 | 110 | 410 | 0 |

| 25 | 70 | 480 | 6/7 |

Figure 1 Schematic diagram for temperature cycle test

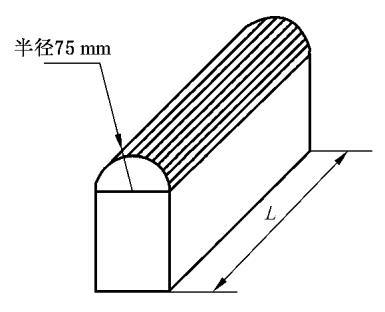

Crush Test

a) Charge to Umax according to Pre Conditioning

b.1) Crush direction: press it in the direction perpendicular to cell polar plate, or in the same direction as the cell most likely to be extruded in the layout of the complete vehicle

b.2) Type of extruded plate: a semi-cylinder with a radius of 75mm, and a length (L) greater than the dimension of the extruded cell

b.3) Crush speed: not greater than 2mm/same

b.4) Crush degree: stop extruding where the voltage is up to 0V, the deformation to 15%, or the extrusion force to 100kN or 1000 times the weight of test object

b.5) keep for 10mins

c) Observe for 1h at the test environment temperature

Figure 6 Schematic diagram for Type I extruded plate